About this deal

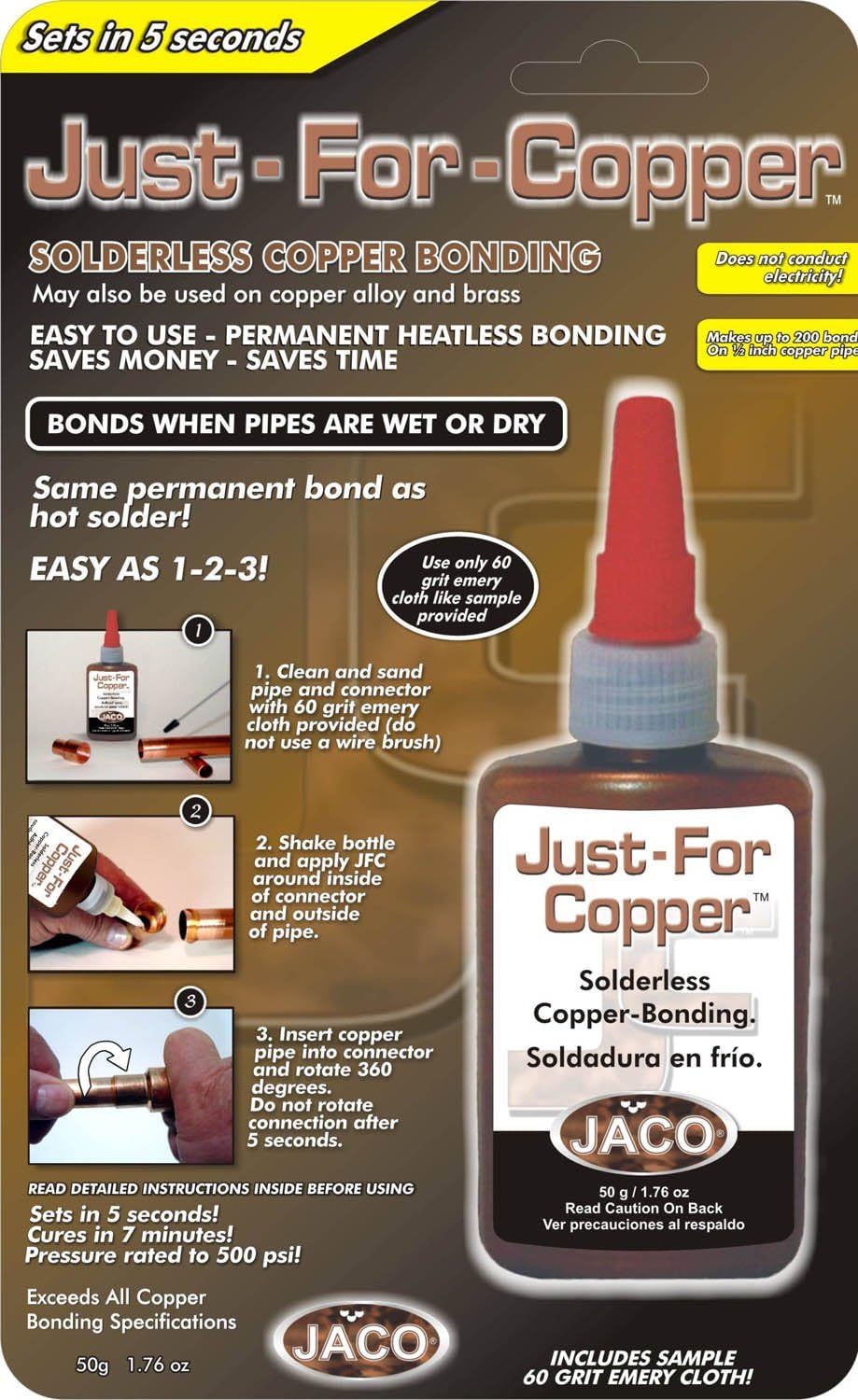

Additionally, it is important to have a clean and dry surface, free from any debris or moisture, to apply the adhesive. This will ensure that the bond is strong and long-lasting.

However, it would help if you did not wait until the glue had solidified before washing, as you may need to apply heat to soften the adhesive. Curing time is an essential part of the copper pipe gluing process, and it must be taken seriously. Always follow the adhesive manufacturer’s recommendations for curing time and conditions to ensure that the joint is strong and leak-proof. Remember to let the joint sit undisturbed during the curing period to prevent premature movement. Leak TestingYou fit ups all have to be straight-true. You can't cram a pipe into a fitting wonky and expect the glue to work. When I hot solder I often 'tweak' things to fit. No doing that with the copper glue.

With this information, you can confidently choose an adhesive that best suits your needs. However, it is recommended to read the instructions provided by the adhesive manufacturer and follow them carefully to ensure a secure and lasting bond. Factors to Consider When Choosing an Adhesive

The adhesive starts hardening within minutes at room temperature and fully cures within 24 hours. You do not need to apply heat. However, short-term exposure to high heat may speed the curing process. No, the pipes need to be completely dry before applying the adhesive to ensure a strong bond. 7. What do I do if the adhesive gets on my skin? Yes, sanding the pipes creates a rough surface that allows the adhesive to bond more effectively and creates a better seal. 4. How long does it take for the adhesive to cure? Before applying Gorilla Glue to your copper pipes, ensure that you meticulously clean and thoroughly dry the surfaces. Any presence of dirt, grease, or moisture can detrimentally impact bonding strength and temperature resistance. Once the surfaces are immaculate, apply a thin and even layer of Gorilla Glue onto both surfaces before firmly pressing them together. For added efficacy, you can employ clamps or exert pressure until the glue cures completely. Just like compression fittings, this one does not require an extra seal using Teflon tape or PTFE tape. It’s because the fitting already comes with an internal O-ring that becomes compacted to ensure a watertight seal.

Leak Prevention: One of the most crucial reasons for properly gluing copper pipes is to prevent leaks as it leads to costly repairs and water wastage. Even a small leak can lead to serious damage to your property if it goes unnoticed for too long. The presence of excess water and moisture can lead to the growth of molds, which can cause serious health hazards. Always allow the adhesive to fully cure before using the bonded parts. For example, after using adhesive to bond copper pipe fittings, wait at least 24 hours before running water through the pipes. Soldering with 50/50 used to be easy once you got the hang of it. It got a bit less easy when lead leaching into the water was noticed as a concern. Still are some plumbers that think the leaching of lead is a red herring. Some have been known to sneak in some 50/50 on difficult joints. A few have been spanked when caught. During the curing process, it’s important to prevent any movement or stress on the joint as it can cause the adhesive to weaken. To avoid premature movement, let the joint sit undisturbed during the entire curing period.Used to join copper pipes to other types of pipes like PVC or ABS pipes. This adhesive has a special formula that can bond two different materials together. Applying the adhesive involves applying primer and cement to the pipes and fittings, then assembling them together. It is important to take your time and follow the manufacturer’s instructions carefully to ensure a proper bond. While this degree of resistance may prove suitable for many applications, it may not be the optimal choice for copper pipes consistently exposed to high temperatures. In such scenarios, it is advisable to utilize adhesives that are specially designed for copper pipes and possess higher temperature resistance. Most epoxy resins require you to mix the epoxy with a hardener before application. The mixture is applied to the parts and starts curing immediately. With a single-component

Great Deal

Great Deal